CAD DESIGNED

PERCISION CUT

Suspension components are engineered to increase strength , durabiltuy and performance..

Delivering the most advanced aftermarket suspension available.

Delivering the most advanced aftermarket suspension available in two options Pro and Sport. Pro models are for racers and aggressive drivers while our sport series out performs factory stock arms and keeps that cold hard cash in your pocket.

Wolfpack stands behind the quality of our products, this is an idustry first,underlining how much we back the quality of our suspension kits.Wolfpack will replace any suspension component failure due to DEFECTS IN MATERIALS AND WORKMANSHIP for a peroid of (2) years from the purchase of an authorized dealer. Warrenty does not cover, wear and tear, driver abuse or crashes. Only manufature defects!

PLAY

RACE

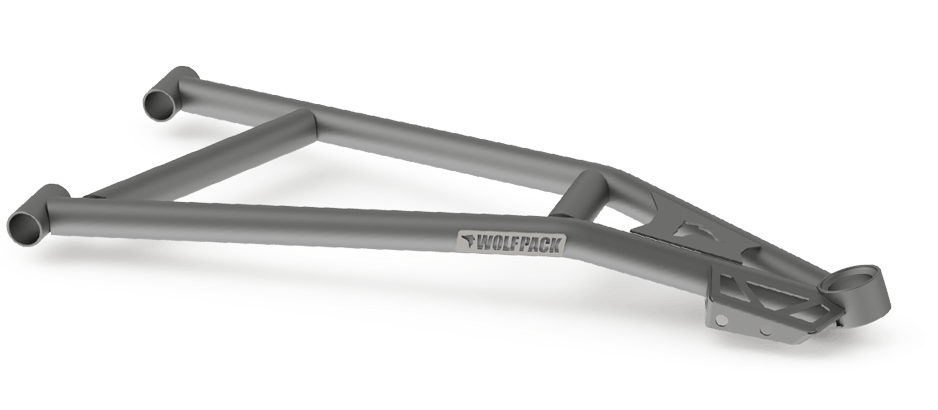

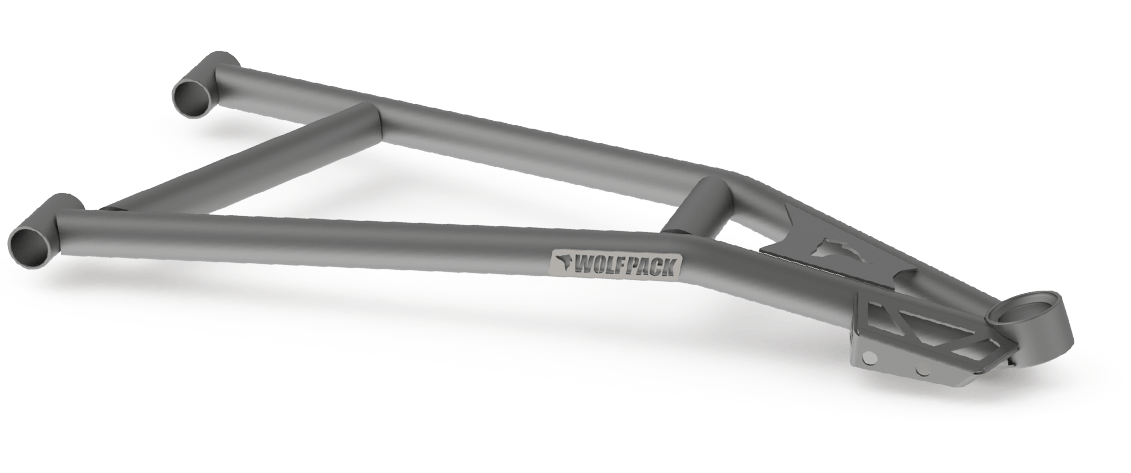

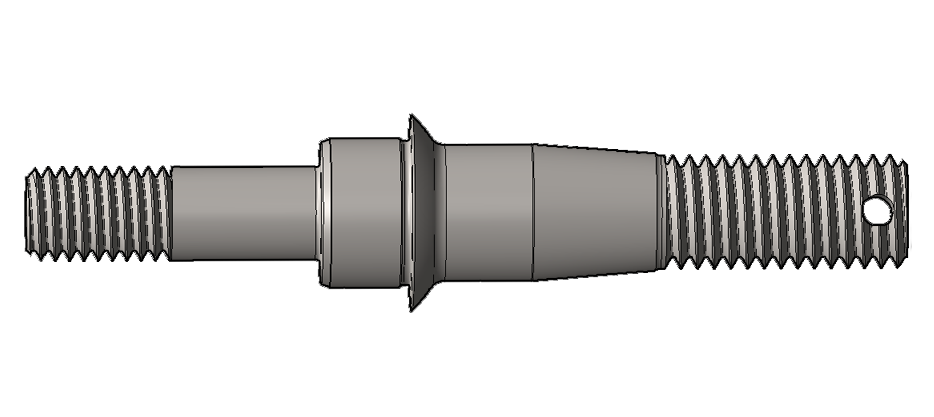

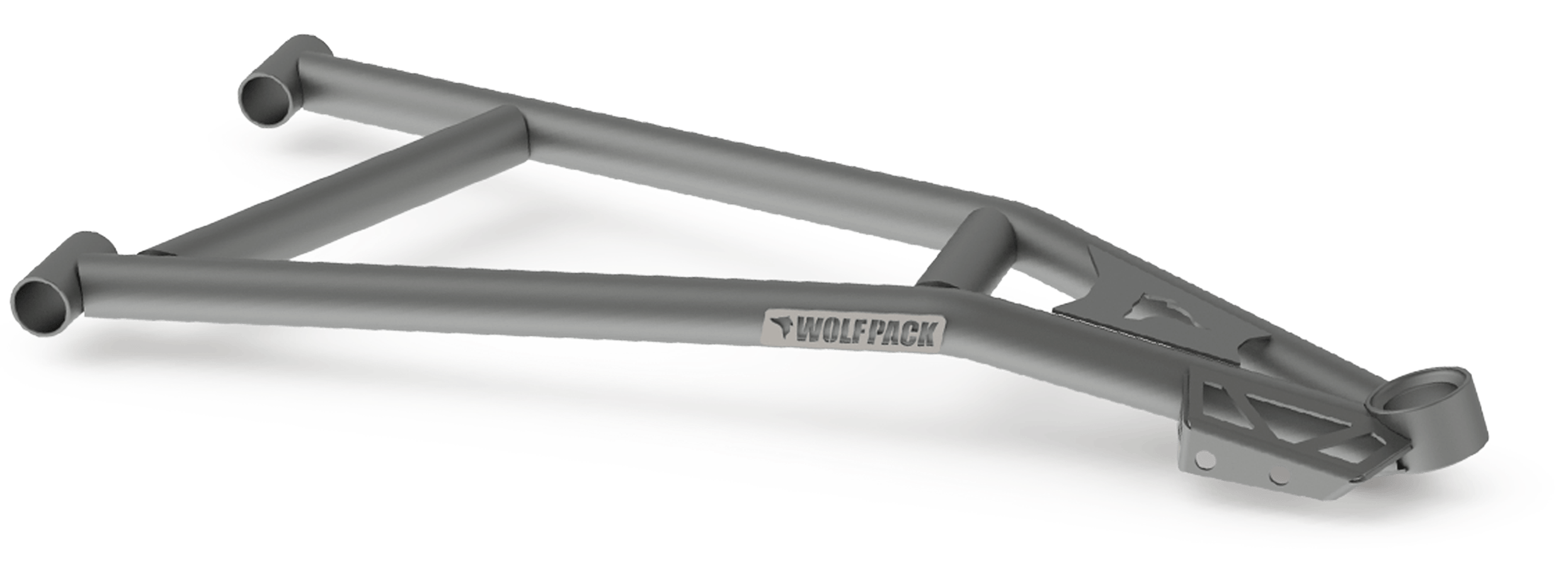

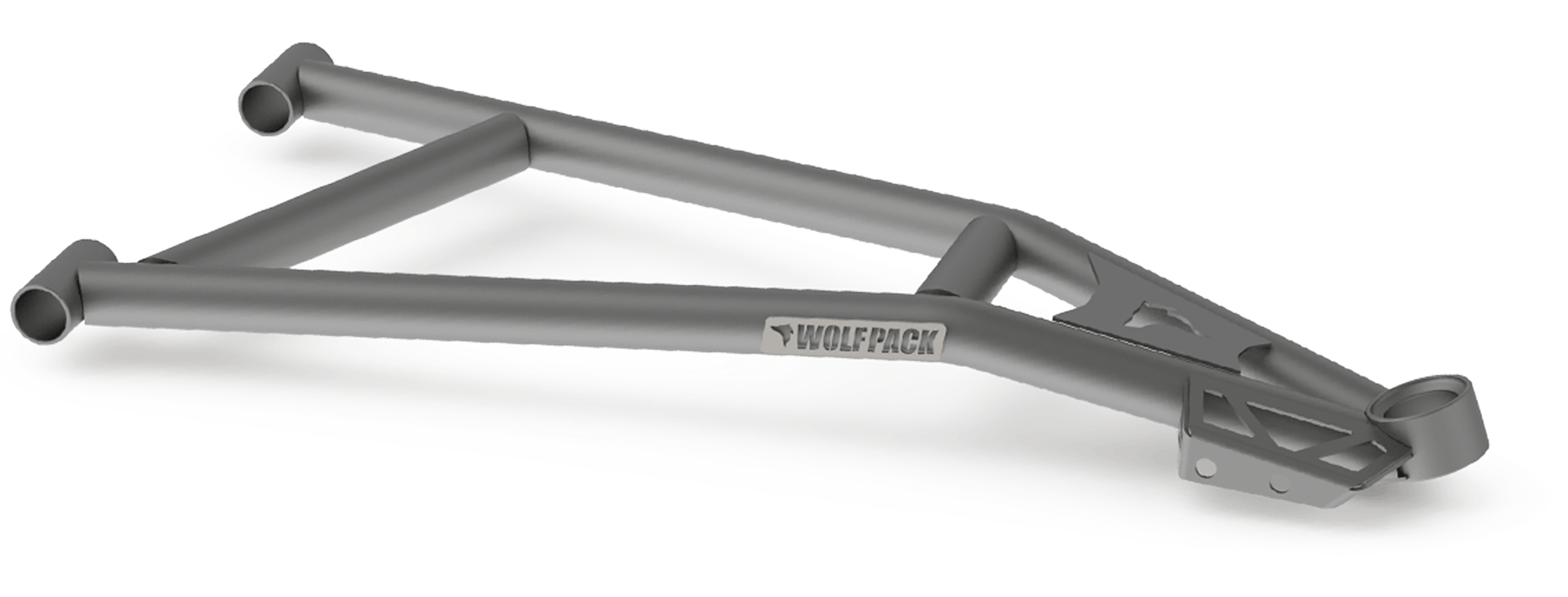

All models are C.A.D designed; CNC precision cut for structural integrity, utilizing DOM or Chromoly. Parts are assembled and welded by our professionals and rigorously tested in real-world race environments

STOCK

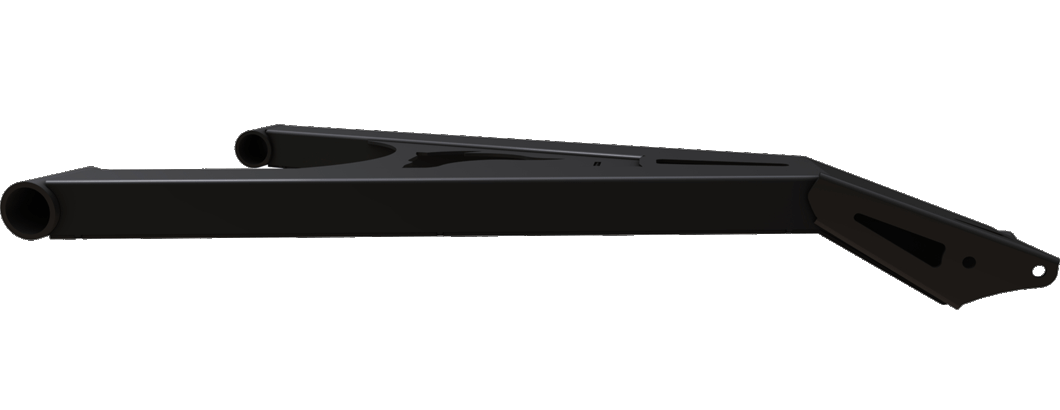

PRO

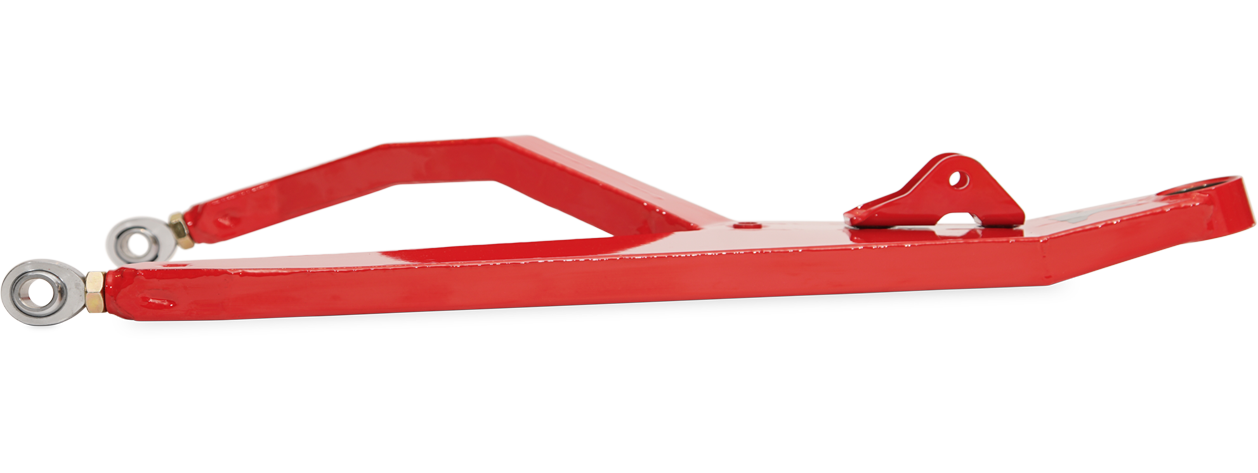

SPORT

HIGH

CLEARANCE

Rocks can (and have) ruin your trip or end a race quickly. Wolfpack Suspension kits feature high clearance placing confidence back in the hands of the driver for smooth and fast driving.

BOXED

TIG

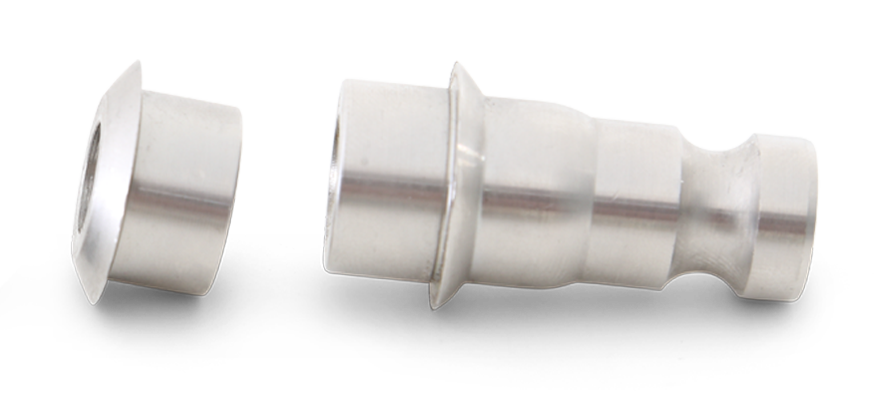

4130 Chromoly, 3/4 Chromoly Rod Ends, Stainless Steel Ball joint Studs, and Delrin bushings are 5X stronger than the factory parts. Wolfpack Arms utilize the factory geometry and widths so they bolt on without the need of buying shocks or after market axles.

4130 CHROMOLY BOXED

4130 Chromoly, 3/4 Chromoly Rod Ends, Stainless Steel Ball joint Studs, and Delrin bushings are 5X stronger than the factory parts. Wolfpack Arms utilize the factory geometry and widths so they bolt on without the need of buying shocks or after market axles.

.

TUBE

MIG

Dom

Stock length DOM tube design feature high-clearance, Stainless Steel Ball joint Studs, Delrin bushings which are 2X stronger than factory parts. Arms utilize the factory geometry and widths so they bolt on without the need of buying shocks or after market axles. CAD designed utilizing Polaris RZR Stock geometry. Design features include high-clearance upgraded ball joints, strength and durability

4130 CHROMOLY TUBE

Wolfpack’s Long Travel tube arms are built with 4130 Chromoly, 3/4 Chromoly Rod Ends, Stainless Steel Ball joint Studs, Delrin bushing, and are 3X stronger than factory components. WolfPsck’s arms utilize the factory geometry and widths so they bolt on without the need of buying shocks or after market axles. Each product is CAD designed utilizing Trophy Truck design features which eliminates the stock ball joint, adding adjustability, overall strength and durability.

FEATURES

Stock length DOM tube designs feature high-clearance, Stainless Steel Ball joint Studs, Delrin bushing, and offer 2X the strength of factory components. Wolfpack Arms utilize the factory Geometry and widths so they bolt on without the need of buying shocks or after market axles. CAD designed to utilize the factory Polaris RZR’s Stock geometry.

Design features include high-clearance upgraded ball joints, which add to the overall strength and durability of the suspension components.

INTELLIGENT DESIGN

Our design process begins with CAD design in solid works. Each design then transitions into a 3D modeling of the design components. Parts are then 3D printed for fitment, prior to machining, enabling our team to quickly make any final changes to design features prior to production. Next process moves into prototype phase with precision CNC machined parts, which are rigorously tested prior to production. The Wolfpack race team then tests each product design many times prior to parts going into final production, ensuring high-quality race proven parts.

CHROMOLY

(1.75 X .095)

DOM

(1.75 X .095)

Chromoly tubing is made from a family of low-alloy steels that contain chromium and molybdenum (SAE 4130) along with iron, carbon and other elements it’s strength-to-weight ratio makes it desirable for aerospace and racecar parts. Chromoly is stronger, lighter and typically more expensive than other types of material. Drawn-over-mandrel (DOM) tubing is a mild steel (SAE 1026) and is typically used for most all UTV cages due to it’s strength, cost and welding processes.

Wolfpack’s long travel suspension is used to dampen the effects of rough, off-road driving conditions and stabilizes the vehicle from rollovers. Baja Racers, Dune Riders, Rock Crawlers and many other types of all-terrain drivers utilize the benefits of long travel suspension components. Stock Geometry suspension is used for strength and durability, stock length utilizes stock axles, eliminating the need for after-market axles. Short-Course Racers, Dune Riders, Jumpers and many other types of all-terrain drivers will benefit from overall stronger suspension components.